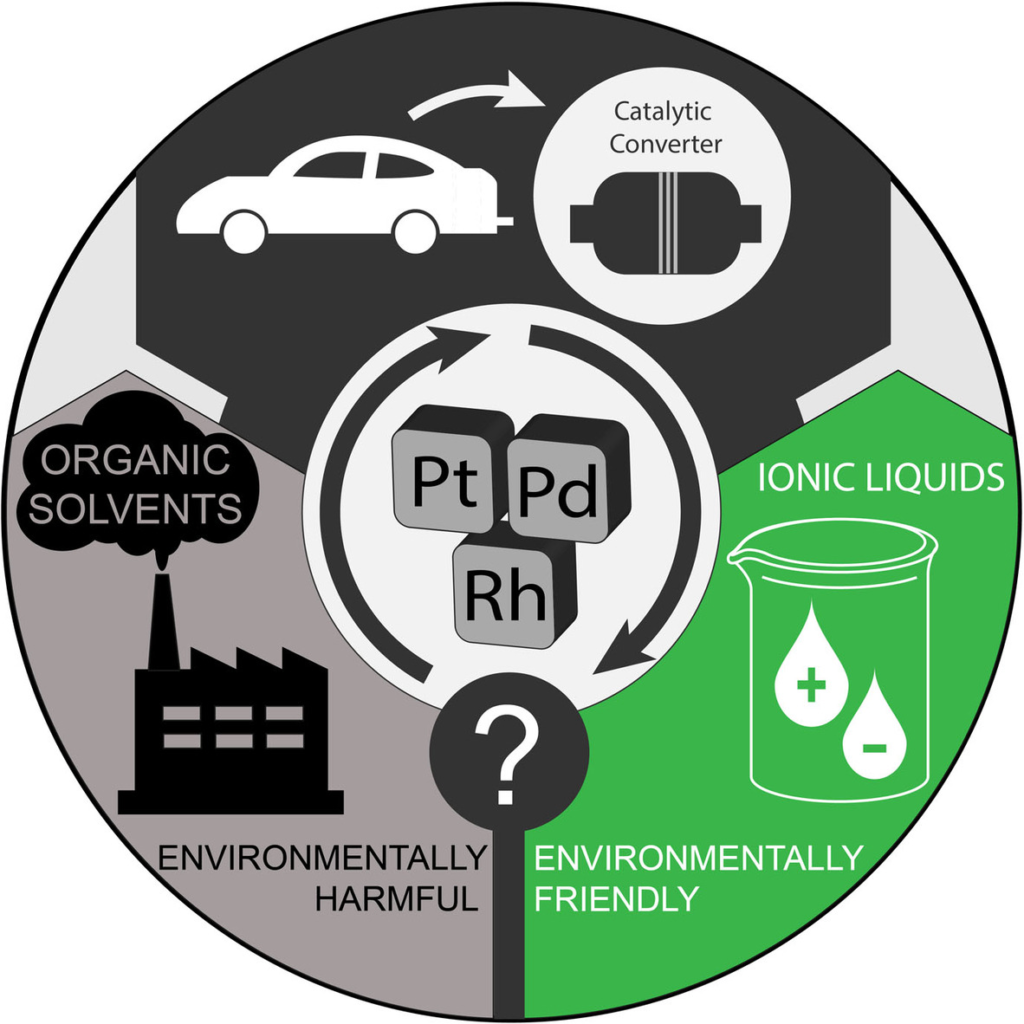

Critical raw material recovery

The EU Raw Materials Initiative (RMI) was adopted in 2008, and represents 41 metals and minerals considered to be of importance to future markets, and of limited supply. Within the European project PLATIRUS (PLATinum group metals Recovery Using Secondary raw materials) we were working on new, green and environmentally friendly developments in leaching, separation and recovery, resulting in higher yields, lower energy consumption and improved environmental impact while avoiding toxic or dangerous reagents such as aqua regia or cyanides.

We are currently transferring metal recovery technologies developed towards different industrial waste streams, for example the extraction of valuable metals (e.g., Zn, Pb, Pt, Pd) present in fly ash, thus allowing its reuse in the construction industry or their disposal as non-hazardous waste.

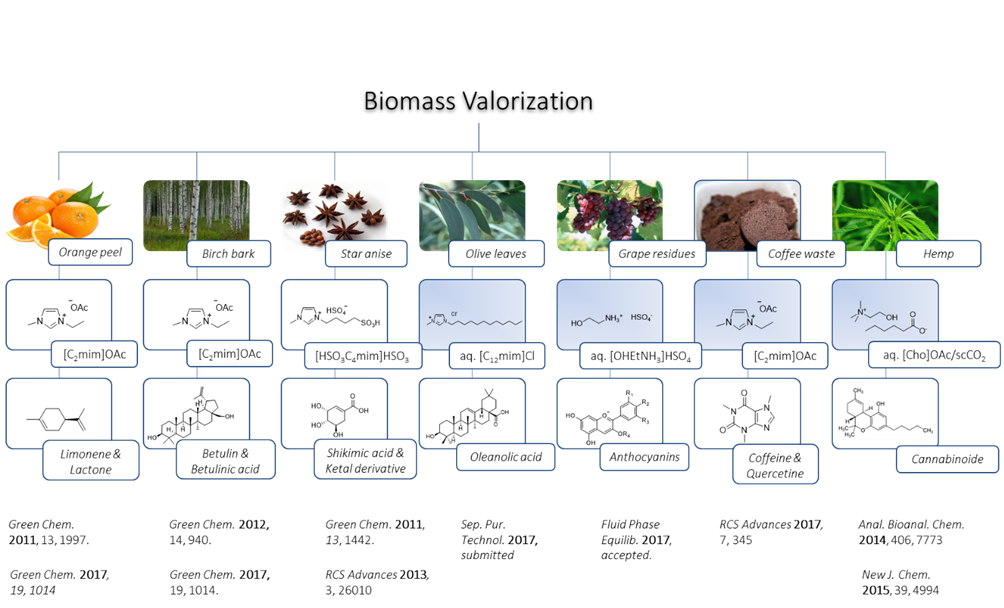

Biomass processing with alternative solvents: Fine chemical production for a value-added biorefinery

Agricultural or biological wastes contain several reusable substances of high value such as chemical intermediates, fragrances or soluble sugars. While the growing research on alternative solvents as solvents for lignocellulosic biorefinery is mostly related to the production of biofuels, relatively little attention is paid to the extraction of valuable ingredients from waste plant materials. Yet there are several aspects of alternative solvents that are potentially advantageous: Apart from their unique solvent properties and potential environmental benefits, they can lead to a better access to valuable ingredient embedded in the biopolymers and contribute to a value-added biorefinery. Over the past years, we developed a platform strategy for the extraction of multiple valuable ingredients from biomass with alternative solvents, and recent example include the isolation of bioactive compounds such as cannabinoids from industrial hemp (Cannabis sativa L.) or the in situ enzymatic conversion and extraction of target compounds from biowaste such as apple pomace